ASME Certified Hose Welding – Metal Hoses

Hose Welding Services

At National Hose & Accessory, our ASME Section 9 certified welders create high-quality metal hose assemblies backed by decades of experience. This certification guarantees our custom metal hose fabrication meets strict safety standards through thorough testing and skill verification.

OEM Metal Hoses

At National Hose & Accessory, we understand OEM metal hose requirements must meet exacting quality and safety standards. Our metal hoses provide flexibility, pressure resistance, and durability in the toughest environments for customers throughout Houston, Pasadena, and South Texas.

What are the best applications for metal hoses when designing equipment?

Metal hoses excel in:

-High-temperature exhaust systems and steam applications

-Cryogenic fluid transfer in petrochemical processes

-Hydraulic and pneumatic systems up to 5000 PSI

-Oil and gas exploration equipment

-Chemical processing plants requiring UHMW or XLPE liners

How do I choose the right metal hose for my OEM application?

We recommend the STAMPED method:

-Size: Inside diameter (ID), outside diameter (OD), and overall length requirements

-Temperature: Operating range from -40°F to 450°F

-Application: Movement needs, vibration absorption, and flexibility requirements

-Media: Chemical compatibility with products like Rubberworx™ or Continental Versachem™

-Pressure: Working pressure ratings from vacuum to 3000 PSI

-Ends: Options including NPT, cam & groove, flanged, or custom fittings

-Delivery: Lead time needs, regulatory compliance, and packaging specifications

What maintenance is required for metal hoses?

-Regular inspections using our OnGuard™ Hose Safety management system

-Correct routing to prevent excessive stress on assemblies

-Clean hoses according to media-specific protocols

-Follow recommended replacement schedules based on application

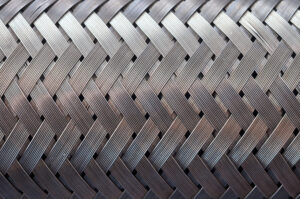

Single or Double Braid Options for Metal Hoses, what is best for me?

Single vs Double Braided Metal Hose Selection Guide

At National Hose & Accessory, we help customers across Houston, Beaumont, and South Texas choose between single and double braided metal hoses based on specific application needs. Your choice depends on pressure requirements, flexibility needs, and the operating environment.

Single Braided Hose

Our single braided metal hose options provide good flexibility while reinforcing against internal pressure. These assemblies work well in moderate-pressure applications (typically up to 150 PSI) where movement is frequent. The Continental Infinity™ Chemical Hose with its single reinforcement layer offers excellent flexibility for operators handling bulk chemicals.

Double Braided Hose

For high-pressure applications in refineries and chemical plants, our double braided metal hoses deliver superior strength and pressure resistance. The Rubberworx™ UHMW Chemical Hose with dual reinforcement can handle pressures up to 250 PSI, making it ideal for environments with constant movement and vibration in petrochemical settings.

FAQs

When should I use a double-braided hose instead of a single-braided one?

Choose our double braided options when working with high-pressure fluids or gases (above 150 PSI), or in applications requiring extended service life. Our double braided metal hose assemblies are commonly used in steam applications up to 450°F where safety is critical.

Does double braiding reduce flexibility?

Yes, our double-braided hoses provide less flexibility due to the additional reinforcement layer. If your application requires tight routing or frequent movement, consider our single braided options with stainless steel reinforcement.

How does braiding affect pressure ratings?

The pressure rating difference is significant – our double-braided assemblies can handle up to 3000 PSI compared to single-braided designs. This makes them essential for demanding industrial applications like high-pressure steam systems at 250 PSI or hydraulic systems up to 5000 PSI.

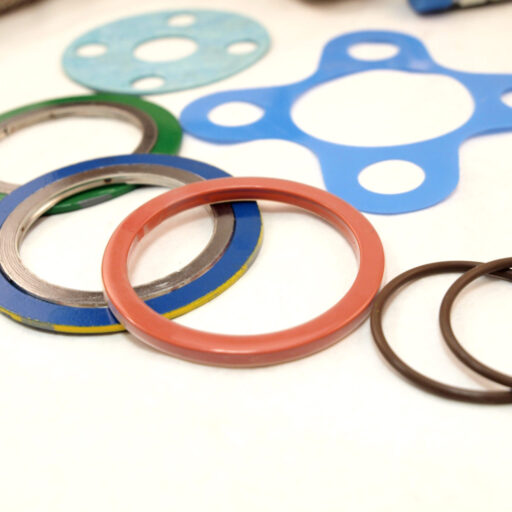

Do I have a wide variety of fittings to choose from with metal hoses and expansion joints?

Metal Hose Coupling Options at National Hose & Accessory

At National Hose & Accessory, we offer various coupling options for custom metal hose assemblies serving the petrochemical, oil and gas, and chemical processing industries throughout Houston, Pasadena, and South Texas. Our metal hoses allow for welding metal couplings directly to the hose for maximum strength and leak prevention.

Available Coupling Types

Flanged Couplings – Perfect for high-pressure applications up to 3000 PSI where frequent assembly/disassembly is needed. Available in 150# and 300# pressure ratings.

Threaded (NPT/BSP) Couplings – Provide secure connections for fluid and gas systems in chemical processing applications. Common in our Rubberworx™ steam hose assemblies.

Hydraulic Couplings Including JIC – Used for high-pressure hydraulic systems up to 5000 PSI with mechanical JIC flare for improved sealing. Part of our hydraulic OE assembly capabilities.

Cam & Groove Couplings – Quick-connect fittings for fast connections in industrial applications. Available in aluminum, brass, and stainless steel, including Dixon Vent-Lock safety cam and groove.

Tri-Clamp Couplings – Standard in sanitary food and pharmaceutical applications requiring clean connections.

Weld Nipple Couplings – Create permanent, high-strength connections for extreme conditions in petrochemical environments.

FAQs

Which metal coupling is best for high-pressure applications?

For applications exceeding 250 PSI, we recommend flanged or weld nipple couplings, which provide stronger, leak-proof seals for steam and chemical transfer applications.

What type of coupling is best for quick connections?

Our Dixon Vent-Lock Cam & Groove couplings allow fast attachment without tools while adding safety features to prevent accidental disconnection during chemical transfer.

How do I ensure compatibility between the coupling and hose material?

Our experts match coupling materials (stainless steel, carbon steel) with your hose to prevent corrosion. For chemical applications, we often pair our UHMW hose with stainless steel couplings for maximum chemical resistance.